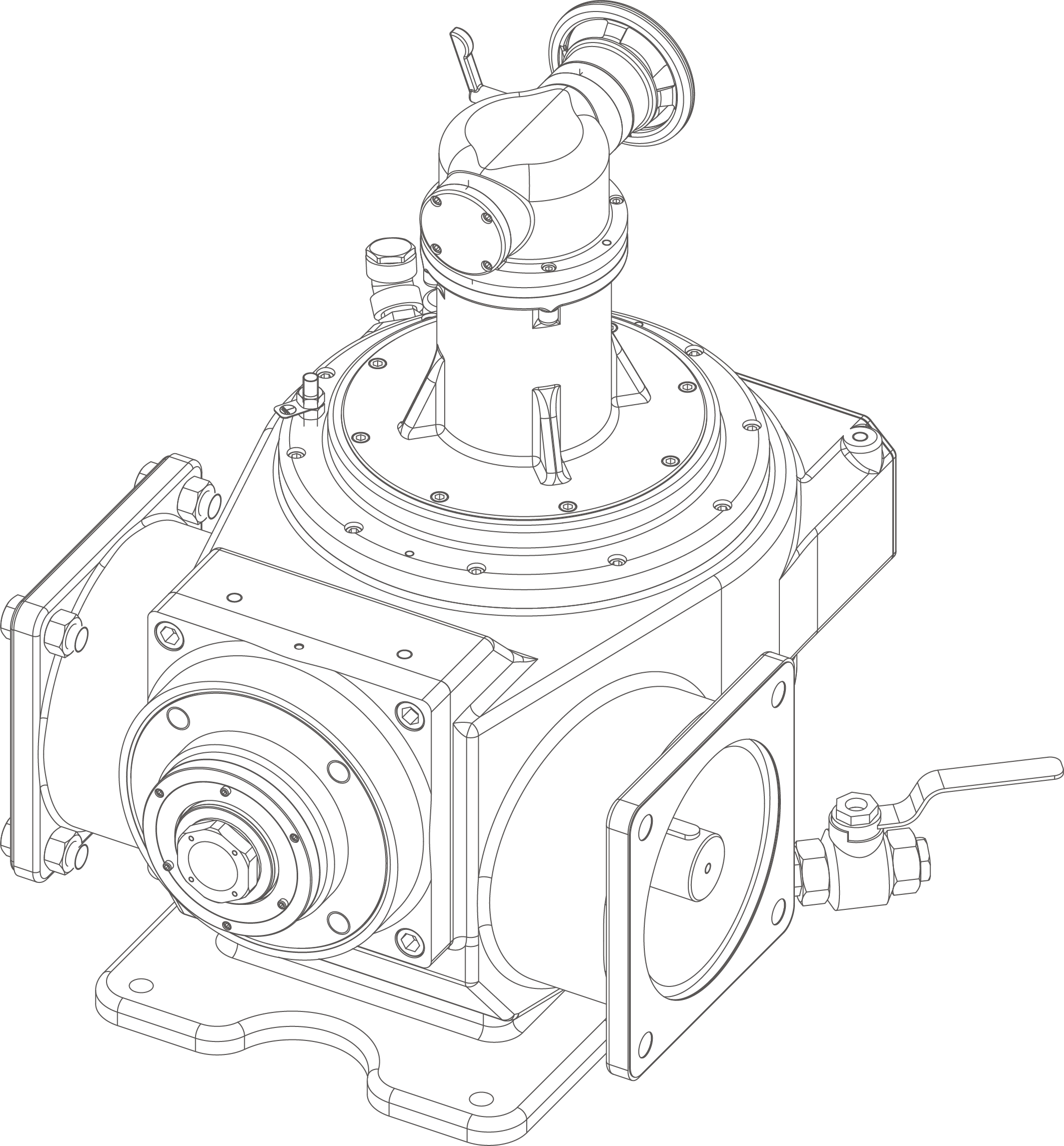

NEXA SERIES

Double-diaphragm and packed plunger pumps with full motion mechanisms

OVERVIEW

Nexa’s exceptional build quality enables stable dosing even under extreme operating pressures and temperatures, from wellhead chemical injection in oil and gas applications to pyrophoric liquids handling in chemical compounds manufacturing.

Designed to meet API 675 3rd edition standard and compliant to Norsok M-501 & M-630, NACE 0175, ATEX2014/34/EU, TR CU 004-010-020-012/2011 and Shell DEP (various), Nexa can be safely operated in hazardous processes, reassuring operators of the pump’s suitability regardless of the application.

Technical Features

| Pressure | up to 600 barg for hydraulic diaphragm and 650 for packed plunger |

|---|---|

| Flow Rate | up to 10,000 l/h with a single head |

| Fluid temperature | from -20°C to 80°C (from -40°C to 150°C on request) |

| Wetter Parts | SS 316L, PP, PVDF and PTFE (exotic alloys available on request) |

Mechanism

Full-motion type in seven different sizes, featuring:

- Oil-bath lubrication

- Low-noise internal worm gearbox

- High-precision stroke adjustment for ultrafine volume control

- Increased turndown ratio achievable via frequency converter

- Housing available in cast iron as standard and nodular cast iron to cope with harsh ambient conditions

- Exakta-designed electrical and pneumatic actuators available

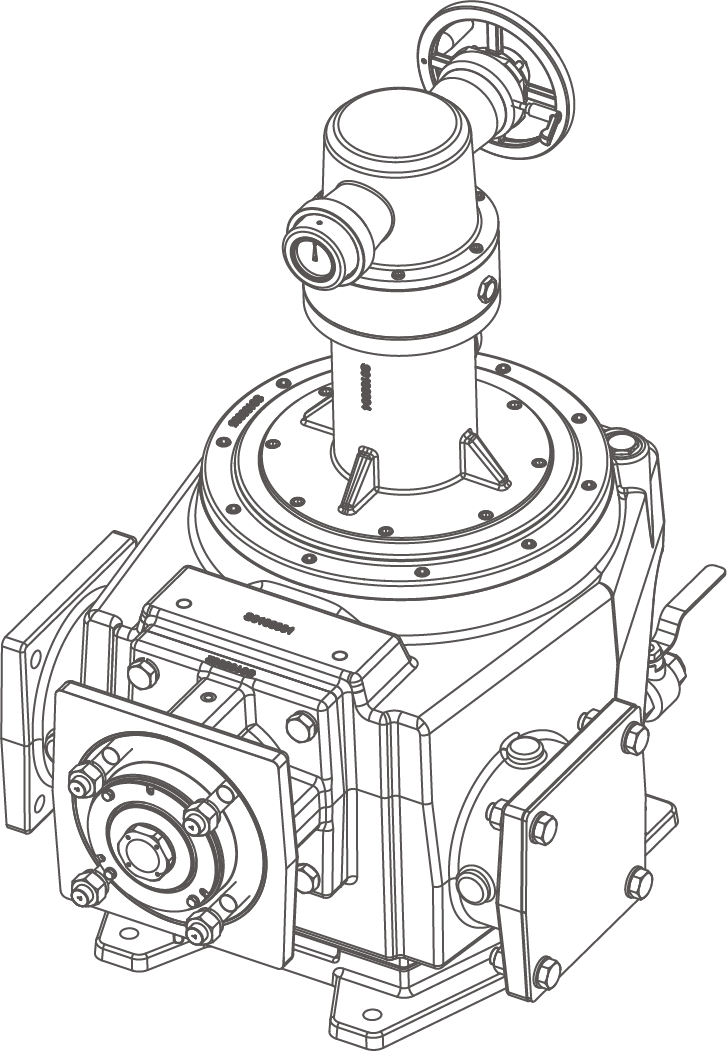

Nexa Mechanism

Technical information

Mechanism available in seven different sizes to ensure maximum reliability and best performances.

N0, N1 Mechanisms

Size | Stroke Length [mm] | Plunger Diameter Range [mm] | Thrust [kN] | Hydraulic Power [kW] |

N0 | 10 | 4 - 50 | 2 | 0.1 |

N1 | 25 | 6 - 90 | 5 | 0.4 |

N2, N3 Mechanisms

Size | Stroke Length [mm] | Plunger Diameter Range [mm] | Thrust [kN] | Hydraulic Power [kW] |

N2 | 35 | 10 - 120 | 8 | 1 |

N3 | 50 | 15 - 130 | 18 | 3 |

N4, N5 Mechanisms

Size | Stroke Length [mm] | Plunger Diameter Range [mm] | Thrust [kN] | Hydraulic Power [kW] |

N4 | 70 | 30 - 130 | 30 | 5 |

N5 | 70 | 35 - 140 | 45 | 6,5 |

N6 Mechanism

Size | Stroke Length [mm] | Plunger Diameter Range [mm] | Thrust [kN] | Hydraulic Power [kW] |

N6 | 120 | 35 - 145 | 60 | 15,7 |

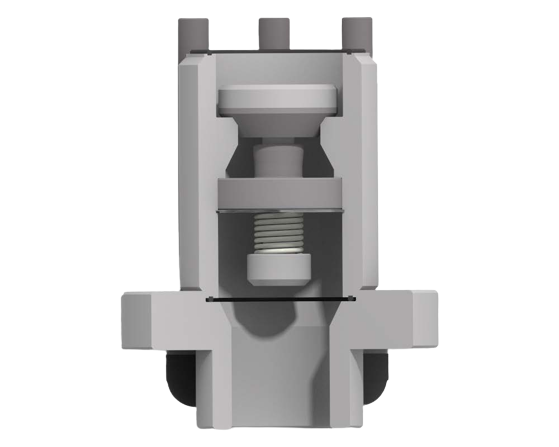

Valves

Exakta is committed to developing flexible and customized valve configurations with flow channels specifically designed to improve hydraulic efficiency while coping with different conditions and applications.

SEAM Cone Valve

Thanks to additive manufacturing technology, delivers high performance with SS 3D printing while allowing endless shape possibilities to meet unique in-valve fluid dynamics for every application.

Features

- Lower NPSH required (up to 10%)

- Increased volumetric efficiency (3%)

- 30% lighter than conventional machined valves

- Enhanced durability for longer mean time between repair

VEEP Cone Valve

Engineered to cater to diverse fluid demands, VEEP Cone Valve offers outstanding performance while ensuring self-cleaning functionality. Its unique operating direction prevents fluid obstruction to the valve’s seals and guide, enhancing its reliability.

VEEP Cone Valve’s design incorporates a component of engineered polymer compound that provides excellent protection against abrasive fluid particles, ensuring compatibility with particulate and abrasive fluids.

Features

- Lower NPSH required (up to 10%)

- Compatibility with particulate fluids

- Compatibility with abrasive fluids

Advantages at a glance

Nexa also allows different-sized mechanisms to be coupled, with casings designed to maintain the same foot level in order to allow installation on a flat support base.

An internal gearbox allows pumps with different stroke adjustment to be combined to form multihead units for greater flexibility.

Mechanisms are coupled together using joints with no exposed parts, resulting in a compact unit with a strong and perfectly-aligned connection which removes the need for a special base.

As process demands for changes in process conditions, users can quickly and easily add a pump to an existing system by performing a few simple coupling operations, even on site.

Industry Applications

Sour water for stripper column

Multi-compound fertilizers production

You might be interested in

Need our Help?

Contact Us

Your request has been sent!

A member of our team will be contact shortly